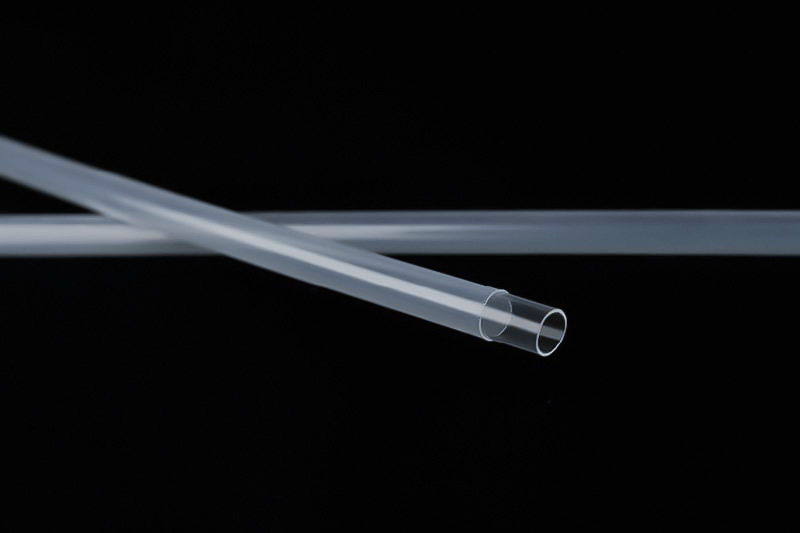

Heat-Shrink Tubing: An Effective Solution for Many Applications

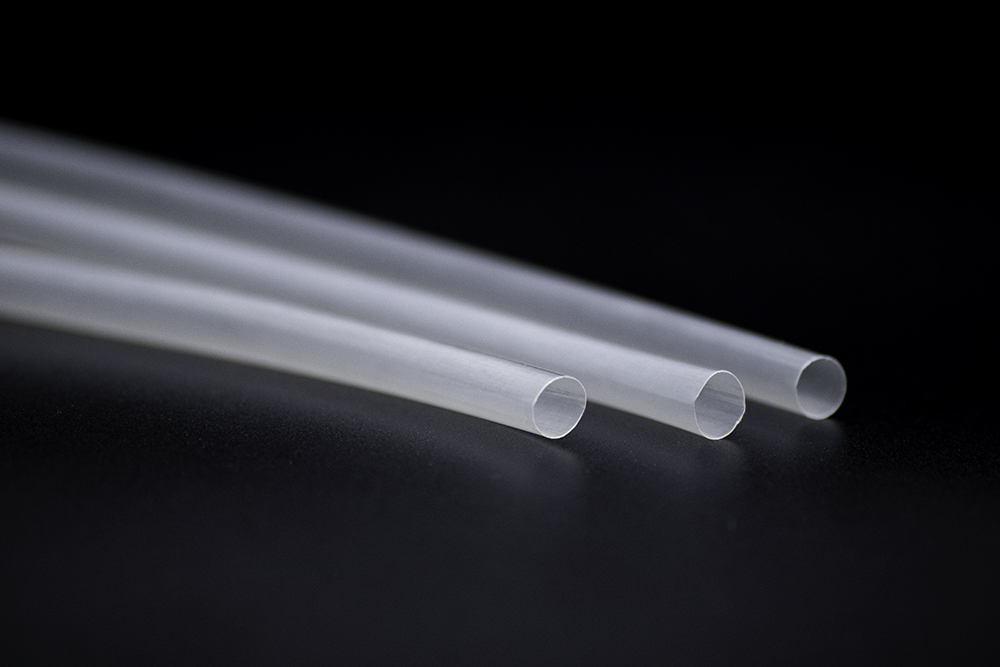

Heat-Shrink tubing is more than just a simple tube. It is an innovative tool used in a variety of applications, from electrical installations to complex cable harnesses.

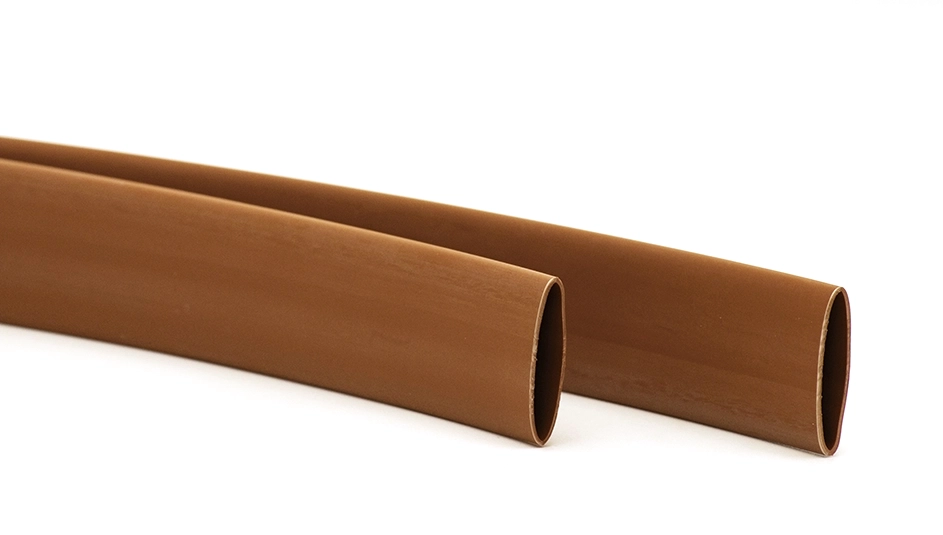

Shrink tubing is made of thermoplastic material that contracts when heated. This makes heat-shrink tubing ideal for numerous applications, especially for protecting electrical connections, bundling cables, and insulating wires.

Frequently Asked Questions about Shrink Tubing

What is shrink tubing used for?

Heat-shrink tubing is often used to insulate, protect, and reinforce electrical cables and wires. It can also be used to coat objects like tools and handles to provide added grip and insulation.

What does shrink ratio mean for shrink tubing?

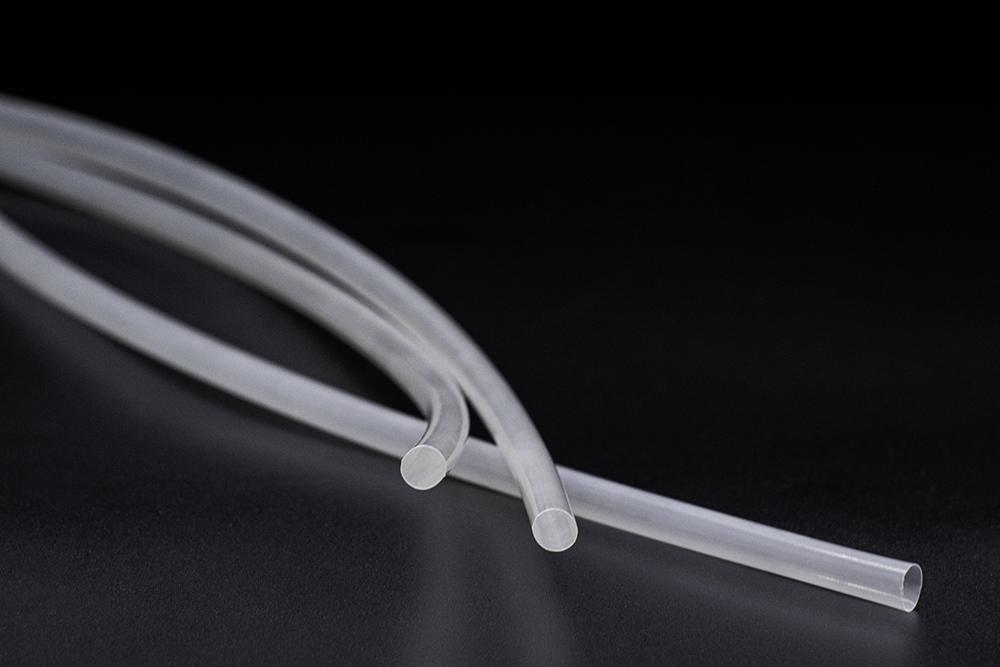

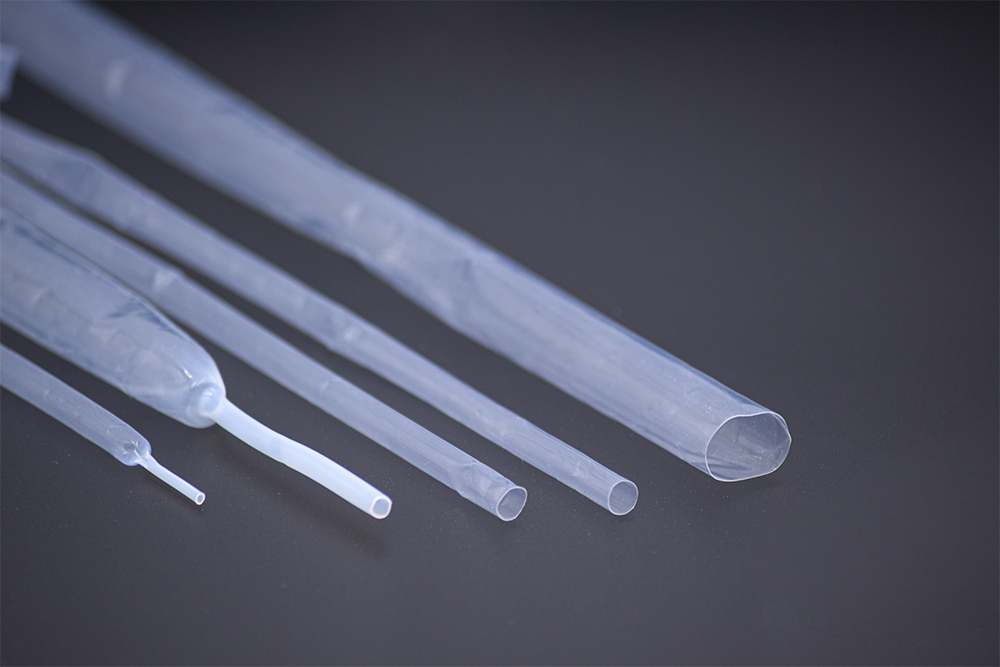

The shrink ratio (also known as shrink factor) for heat-shrink tubing refers to the ratio between the initial diameter of the shrink tubing and the diameter it reaches after being heated and contracted. This ratio is expressed as a number, such as 2:1, 3:1, 4:1, or 6:1.

The shrink ratio is an important factor when choosing the right heat-shrink tubing for a specific application. It must match the diameter of the material to be insulated or connected and the specific requirements for shrinkage. Depending on the application, a higher shrink ratio may be required to ensure better sealing or insulation.

What are the advantages of heat-shrink tubing?

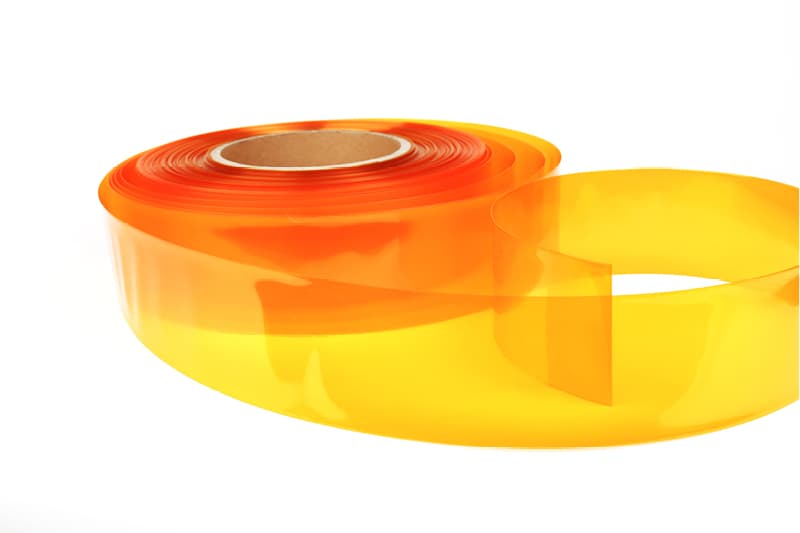

Shrink tubing provides excellent insulation, protection, and support for cables and other objects. It is also easy to apply and can be used in various environments, including wet or corrosive conditions.

Can heat-shrink tubing be removed after installation?

Removing shrink tubing after installation can be difficult because it shrinks tightly around the object. However, there are tools like cutting tools to cut and remove the tubing.

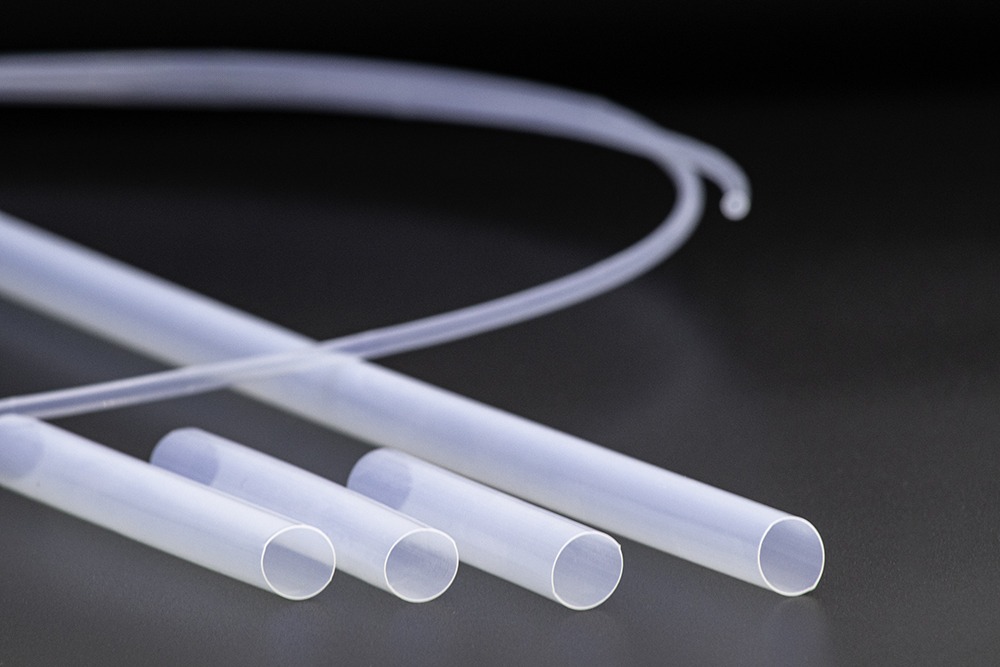

How do you choose the right size and shrink ratio for heat-shrink tubing?

The size of the heat-shrink tubing should be chosen to fit the object it will cover when fully shrunk. The shrink ratio should be chosen to be sufficient to fit the tubing around the object but not so large that it shrinks excessively.

Can heat-shrink tubing be reused?

Shrink tubing cannot be reused after its initial application.

Are there special heat-shrink tubing for use in high-temperature environments?

Yes, there are heat-shrink tubing products specifically designed for use in high-temperature environments, such as in the aviation industry or high-performance engines. These tubing materials have higher melting points, such as PTFE, and can withstand temperatures of up to 260°C.

Can heat-shrink tubing be printed?

Yes, there are shrink tubing products designed for labeling purposes. At BIT, it is possible to have shrink tubing customized printed according to your requirements and needs. Whether it’s a company logo, brand name, barcode, or consecutive serial number, almost anything is possible.

How should heat-shrink tubing be stored?

Shrink tubing should be stored in a cool, dry place to prevent deformation or deterioration. It is also important to protect it from direct sunlight, moisture, and dirt.

How do you remove heat-shrink tubing?

To remove shrink tubing, it can be carefully cut with a sharp knife. However, care should be taken not to damage the object that the tubing encases.

What are the benefits of using heat-shrink tubing?

Shrink tubing offers an effective way to insulate electrical connections, prevent corrosion, and protect electronic components. It is easy to install and provides excellent resistance to moisture, chemicals, and other environmental factors.

Can heat-shrink tubing be used outdoors?

Yes, there are shrink tubing products specifically designed for outdoor use, offering additional resistance to UV radiation and other environmental factors.

Can heat-shrink tubing be cut to the desired length?

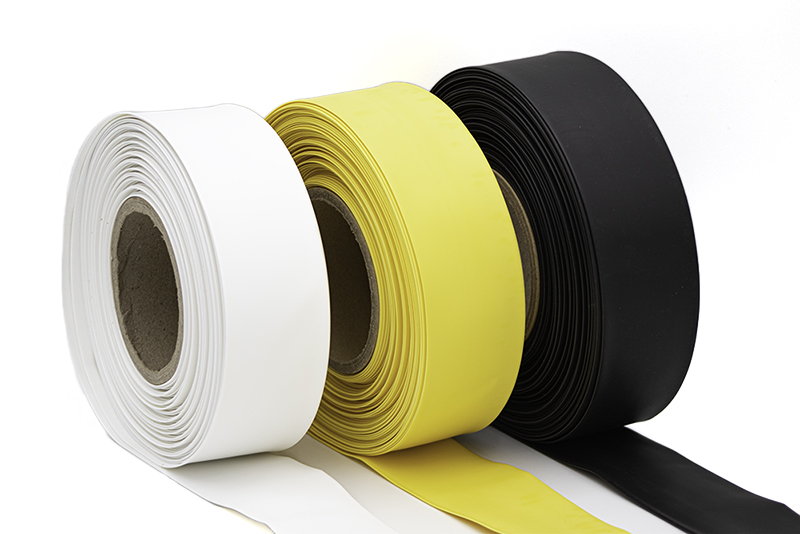

Yes, shrink tubing can be cut to the desired length before installation. BIT offers tubing assembly with tight length tolerances, high cutting accuracy, and flexible implementation with very short lead times.

How can premature shrinking of heat-shrink tubing be prevented?

To prevent premature shrinking of shrink tubing, it should be stored in a cool, dry place and protected from direct sunlight and high temperatures.

Can heat-shrink tubing be purchased in different colors?

Yes, shrink tubing is available in a variety of colors to meet different requirements and needs. The color can also help with the identification of cables or other components.

What applications are heat-shrink tubing suitable for?

Heat-Shrink tubing is highly versatile and suitable for a wide range of applications. Some of the most common applications include:

Electrical Engineering/Power Technology: Shrink tubing is often used in electrical engineering to insulate and protect cables and wires. It can also be used to protect electronic components such as circuit boards and connectors.

Mechanics: In mechanics, shrink tubing is frequently used to protect and insulate pipes and hoses. It can also be used to label and identify tools and other equipment.

Automotive: In the automotive industry, shrink tubing is used for insulating and protecting cables and wires. It can also be used to repair damage to cables or hoses.

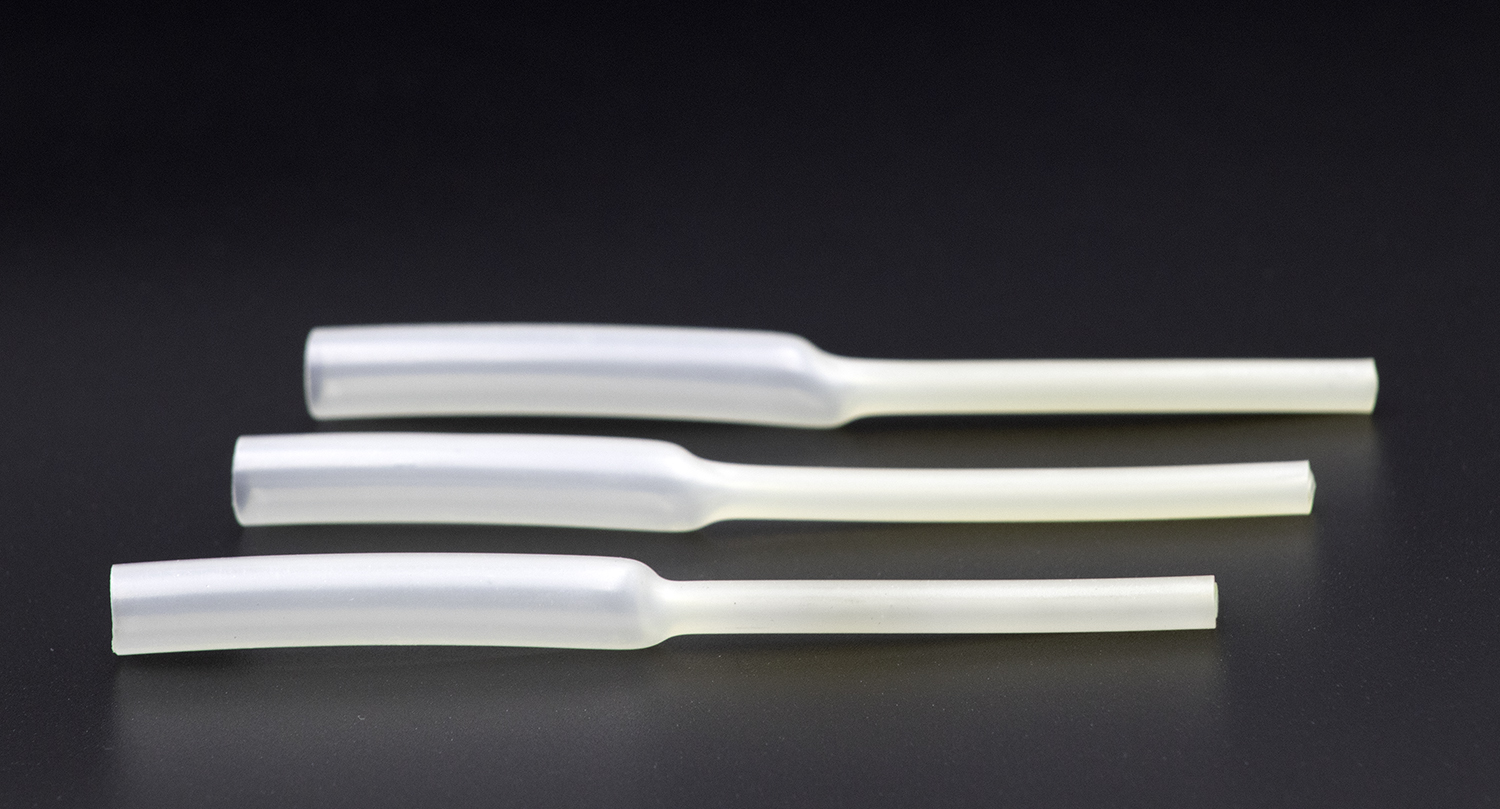

Medical Technology: Shrink tubing can also be used in the medical field, such as in the production of catheter or endoscope tubing.

In general, shrink tubing can be used in any area where the protection, insulation, or labeling of cables, hoses, or devices is required.